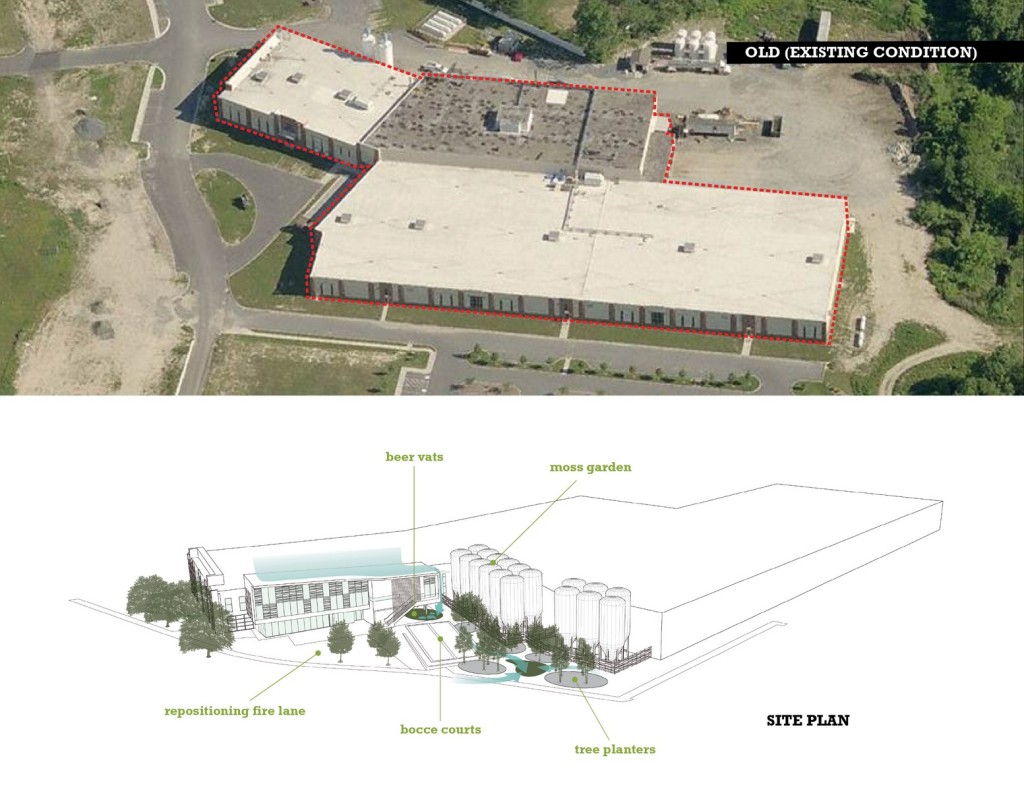

Founded in 1995, Dogfish Head creates some of this country’s most fascinating and adventurous craft beers. After outgrowing its Rehoboth Brewpub, the company adopted a 104,000sf cannery in Milton, Delaware to house its brewing operations in 2002. Recent production demands of the growing company required much-needed office, laboratory, and retail space, which offered an opportunity to reshape the image of the existing complex into one more attuned to the company’s progressive and “off-centered” culture.

Architect: DIGSAU

Location: Milton, Delaware

Project Team: Jules Dingle, Jeff Goldstein, Mark Sanderson, Jamie Unkefer, Aaron Jezzi

Structural Engineer: Baker, Ingram & Associates

Contractor: Lighthouse Construction, Inc

Interior Casework and Work Stations: Fleetwood Fixtures

Steampunk Treehouse: Sean Orlando and 5TC

Project Area: 26,000 sqf

Project Year: 2009

Photos: Pixelcraft Inc. / Roman Torres

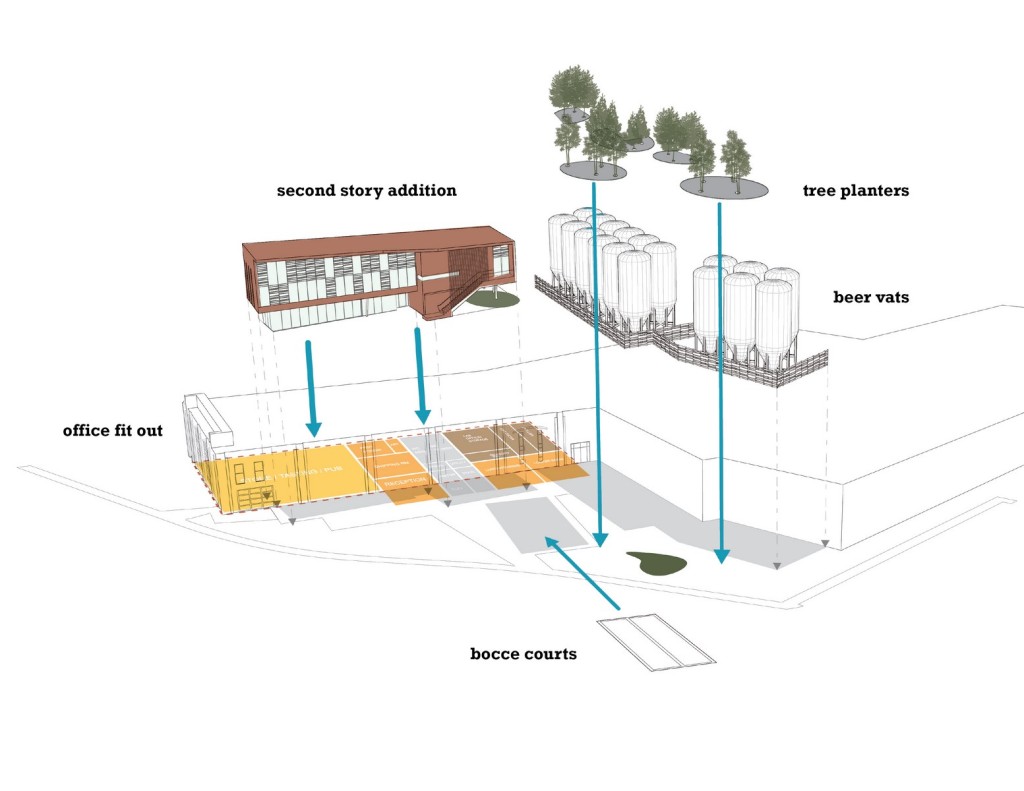

In order to meet the production demands of this rapidly growing company, the project went from design to occupancy in just 11 months. The project began as an interior fit out, but a programming analysis revealed the need for additional space, doubling the scope of the project. The fit-out expanded into a new addition and an opportunity to disrupt the symmetry of the brick and stucco facility in favor of something in-line with their “off-centered” philosophy.

Along with the building expansion and fit-out, a new site design comprehensively transforms the former fire access road into an entry plaza featuring two regulation bocce courts and an additional conference room in the form of the Steampunk Treehouse.

The project integrates straight-forward techniques to achieve efficiencies in use of material, water, and energy. The site design incorporates infiltration areas and pervious surfaces over what had previously been impervious pavement. Daylight modeling was utilized to locate windows and roof monitors, minimizing the need for artificial light. Most interior lighting is provided by high-efficient LED fixtures integrated into the steel joists. Local and salvaged materials were utilized for the cladding and furniture.

Prev Post

Residential Development | FBN Architects

2 Mins Read

Next Post

Algae Green Loop | Influx Studio

6 Mins Read