Rapid Housing Initiative funding from Canada Mortgage and Housing Corporation presented an opportunity to continue CityHousing Hamilton’s mission of building affordable housing that is safe, well-maintained, cost-effective, and supports the diverse needs of their communities.

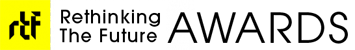

Rethinking The Future Awards 2025

Third Award | Sustainable Project of the Year (Built)

Project Name: 1620 Main St. E.

Category: Sustainable Project of the Year (Built)

Studio Name: mcCallumSather

Design Team: Matt Bolen, Morgan Wright, Christina Boyer

Area: 28, 500 sq. ft.

Year: 2025

Location: Hamilton, ON

Render Credits: N/A

Other Credits:

1620 Main Street East represents the second phase of the Motor City Hotel site redevelopment, providing much-needed affordable housing adjacent to the Queenston Traffic Circle in Hamilton.

This six-storey, 28,500 square foot building reflects CityHousing Hamilton’s commitment to delivering high-quality, sustainable, and affordable housing. Designed to achieve Passive House Classic certification, the project also embraces mass timber construction, demonstrating a progressive approach to reducing both operational energy and embodied carbon. Combining Passive House principles with prefabricated construction allows the project to achieve stringent performance targets while maintaining cost control and meeting the accelerated schedule set by the Rapid Housing Initiative.

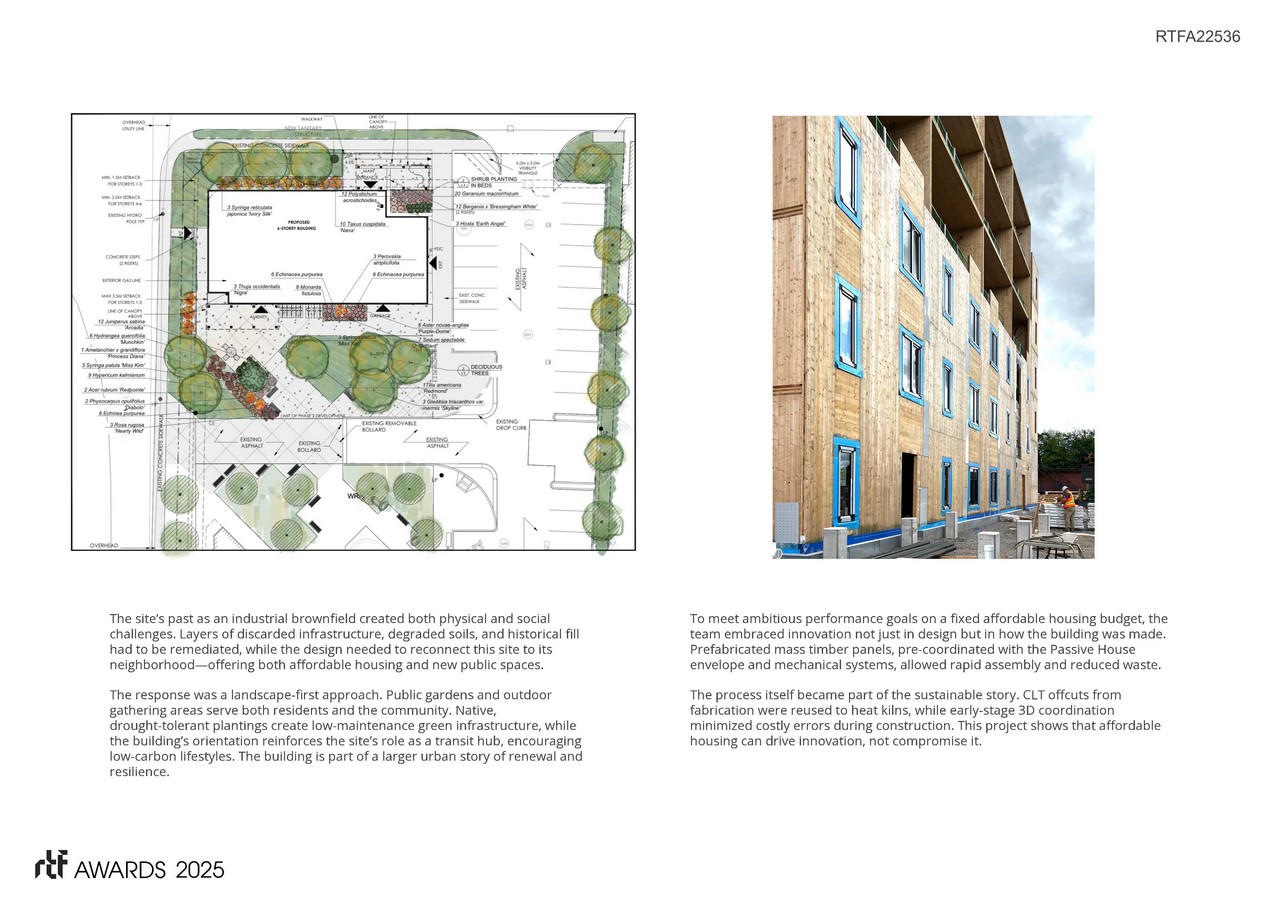

The project’s site, formerly home to the City Motor Hotel, required extensive rehabilitation before construction could begin. Beneath the surface, the team uncovered layers of discarded infrastructure, fill from previous developments, and aging retaining walls. This remediation process was also an opportunity to reconnect the site to the community by introducing new public spaces and outdoor amenities that serve both residents and neighbours.

A resilient landscape strategy was developed using drought-tolerant, native plantings designed to thrive with minimal maintenance. These plantings contribute to local biodiversity while helping manage stormwater on site. The result is an outdoor environment that fosters both environmental and social sustainability.

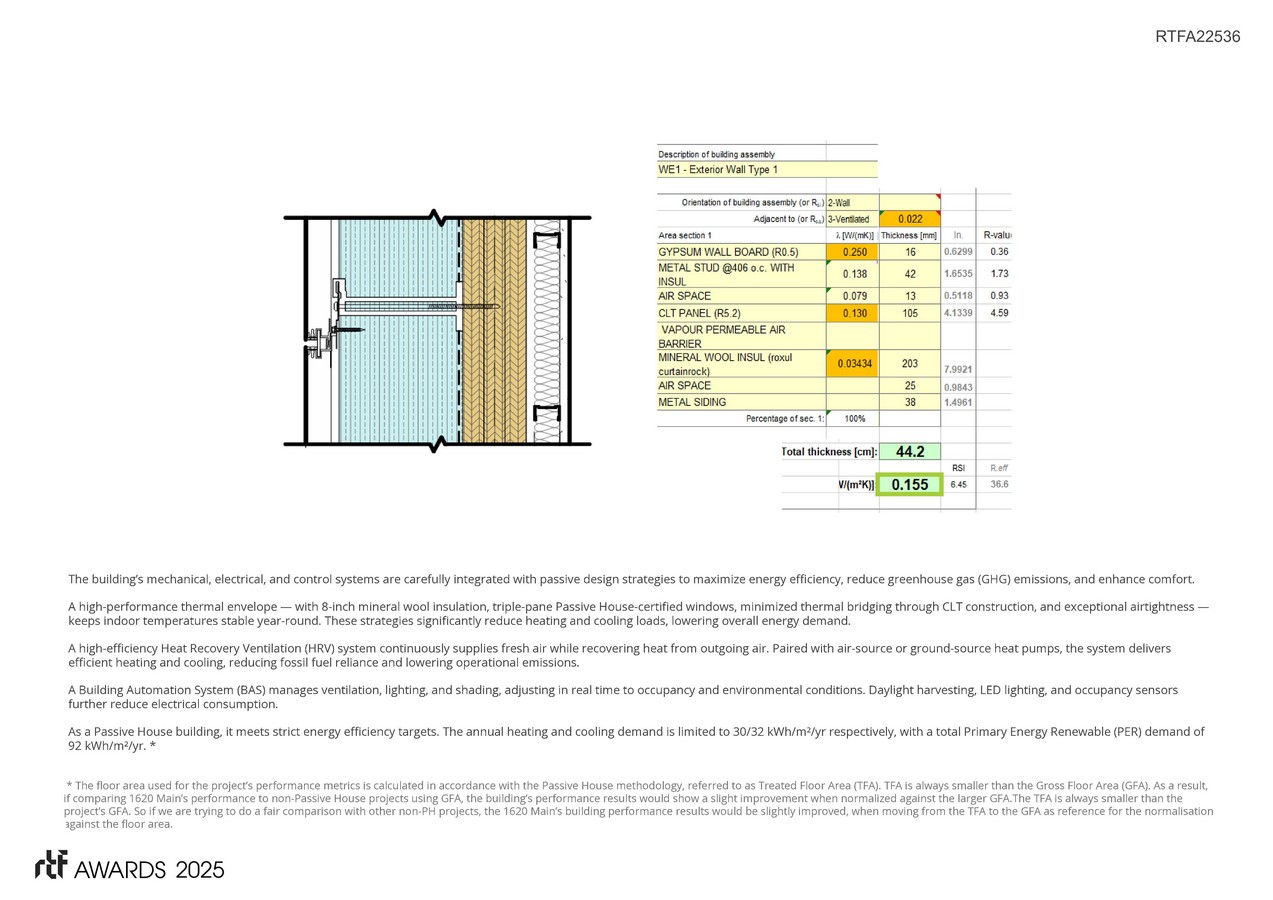

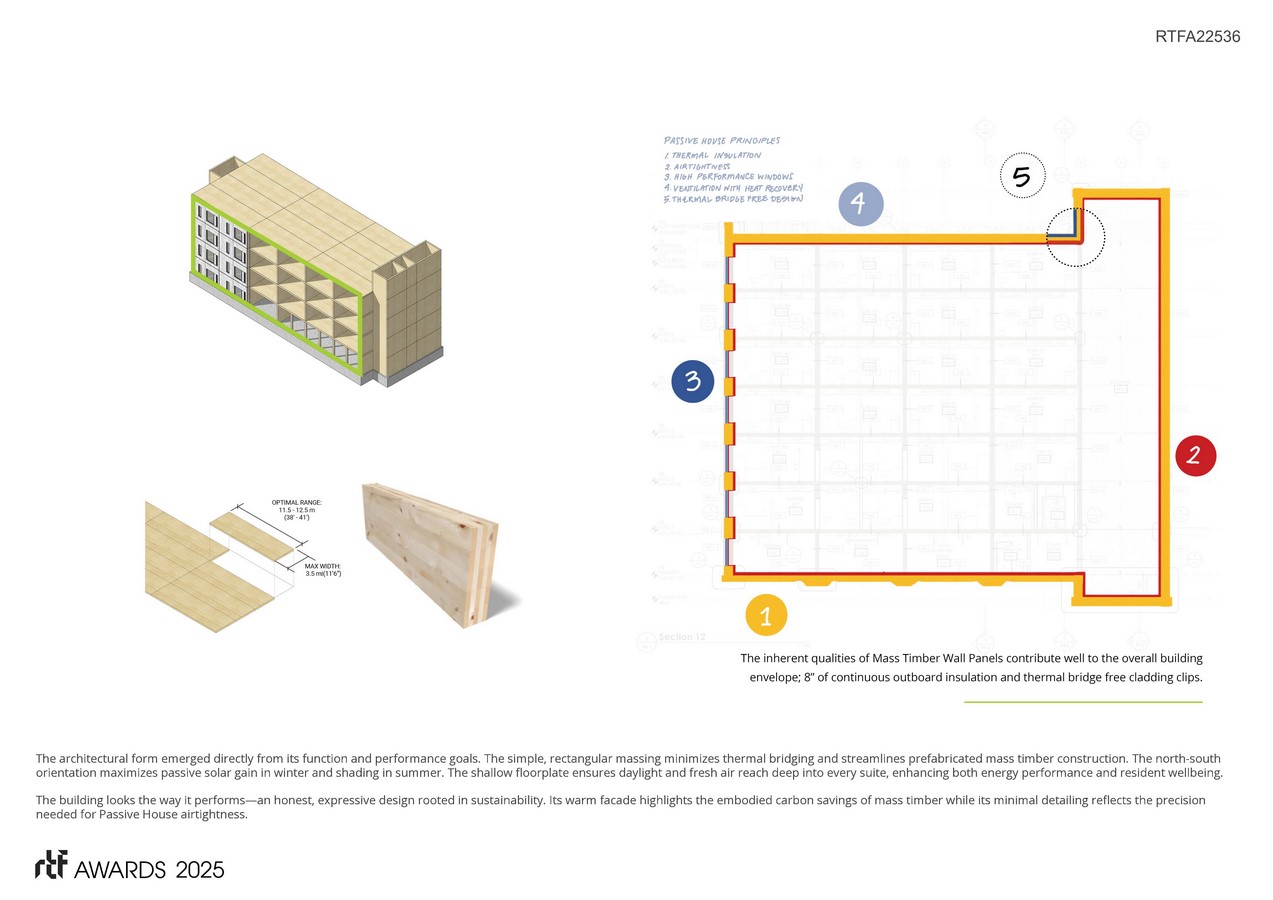

The building’s design evolved directly from its performance goals. Passive House certification required careful attention to airtightness, insulation, and thermal bridging, while mass timber prefabrication demanded precise detailing and coordination. The simple, rectangular form optimizes energy performance while aligning with efficient prefabrication techniques. Prefabricated Cross-Laminated Timber (CLT) panels allowed for rapid assembly and reduced construction waste, helping meet both budget and timeline constraints.

The building envelope is a high-performance system designed to exceed Passive House requirements. Triple-glazed windows, over-insulated by one inch, were installed using Cascadia thermal clips to significantly reduce thermal bridging. The shallow floorplate ensures that 95% of living spaces are within seven meters of an operable window, maximizing natural light and ventilation while reducing reliance on mechanical systems.

The mechanical design also supports the project’s sustainability goals. A central heat recovery ventilation (HRV) system delivers continuous fresh air while capturing outgoing heat, contributing to ultra-low energy use. Careful coordination between the design team, mechanical engineers, and mass timber fabricators ensured penetrations were minimized, preserving the building’s airtightness.

The selection of mass timber as the structural system contributes to a significantly lower embodied carbon footprint compared to traditional concrete or steel. Beyond its environmental benefits, mass timber provides a warm, natural aesthetic that enhances interior comfort. Prefabrication off-site further reduced waste and accelerated construction. In keeping with circular economy principles, wood offcuts from the CLT production process were repurposed to fuel factory kilns, minimizing waste and embodied carbon.