Unfold Form is an innovative, lightweight, and reusable formwork system that enables the rapid construction of sustainable vaulted floors. It rethinks floor construction by integrating sustainability, efficiency, and structural innovation.

Rethinking The Future Awards 2025

First Award | Sustainable Project of the Year (Built)

Project Name: Unfold Form: Curved-crease un-foldable formwork for sustainable vaulted floors

Category: Sustainable Project of the Year (Built)

Studio Name: Block Research Group, ETH Zurich

Design Team: Lotte Scheder-Bieschin, Mark Hellrich, Tom Van Mele, Philippe Block

Area: 5.4 m2 (prototype)

Year: 2024

Location: Zurich, Switzerland (prototype)

Photography Credits: Lotte Scheder-Bieschin, Andrei Jipa

Render Credits: Lotte Scheder-Bieschin

Other Credits: N/A

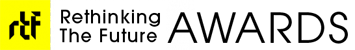

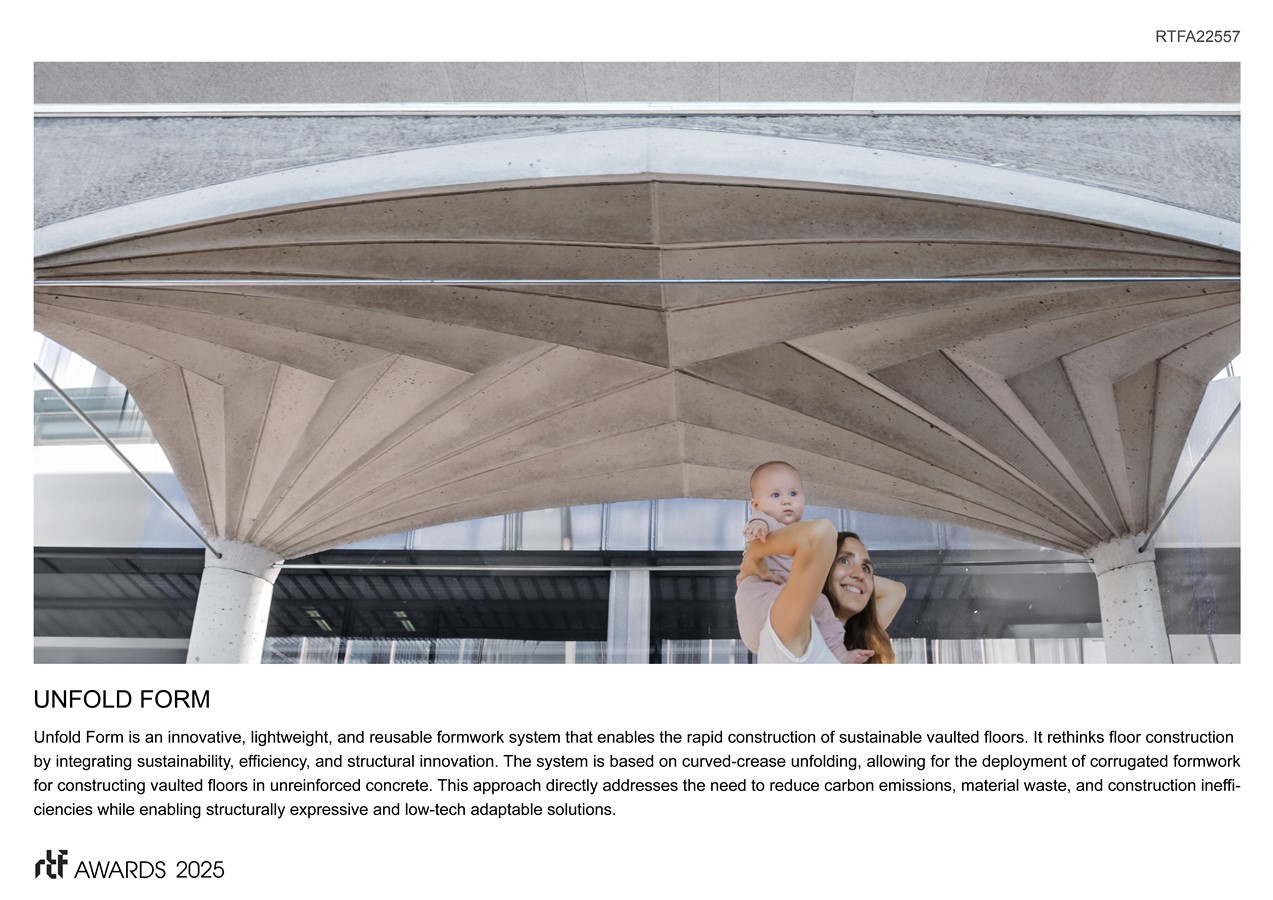

The system is based on curved-crease unfolding, allowing for the deployment of corrugated formwork for constructing vaulted floors in unreinforced concrete. This approach directly addresses the need to reduce carbon emissions, material waste, and construction inefficiencies while enabling structurally expressive and low-tech adaptable solutions.

Sustainability through Structural Geometry

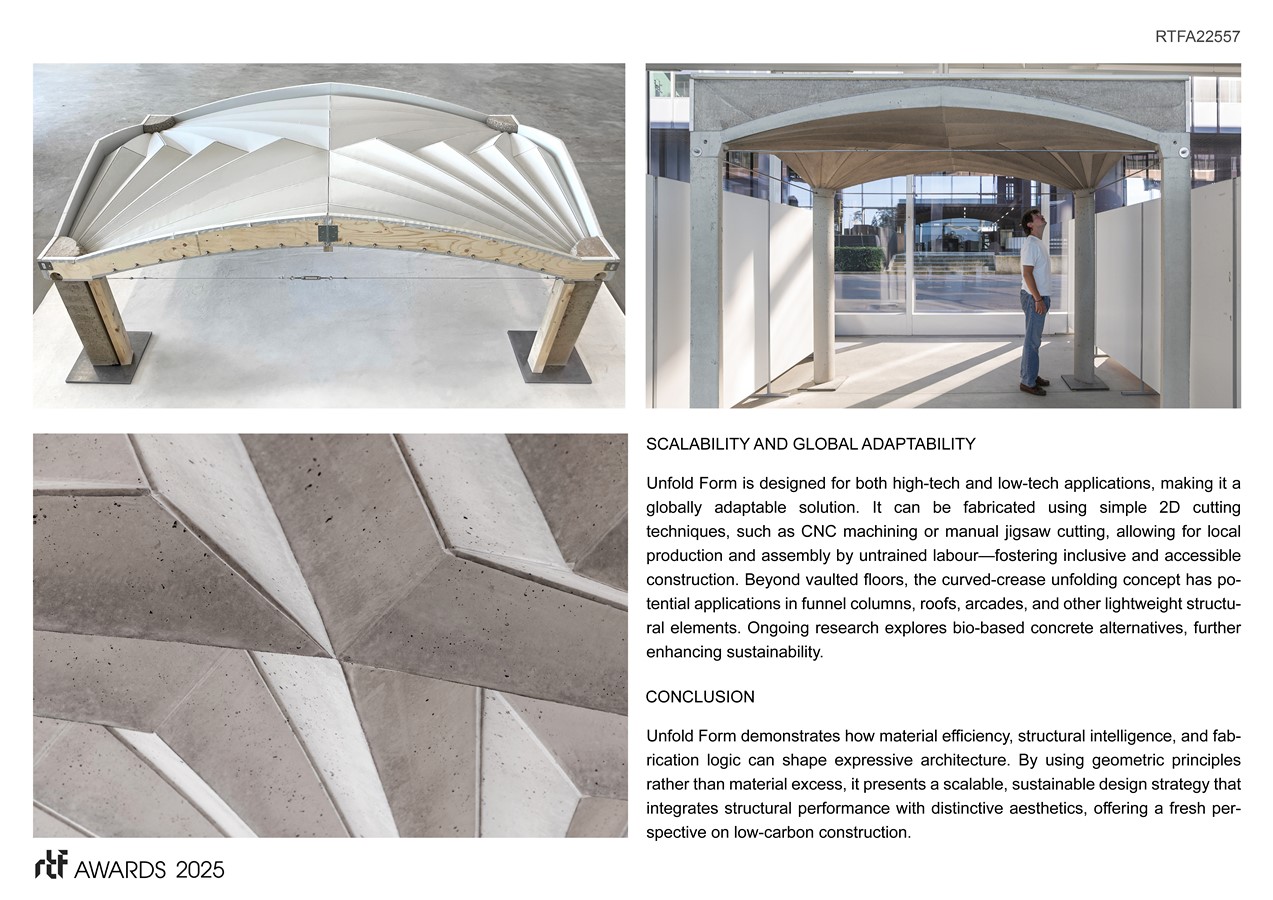

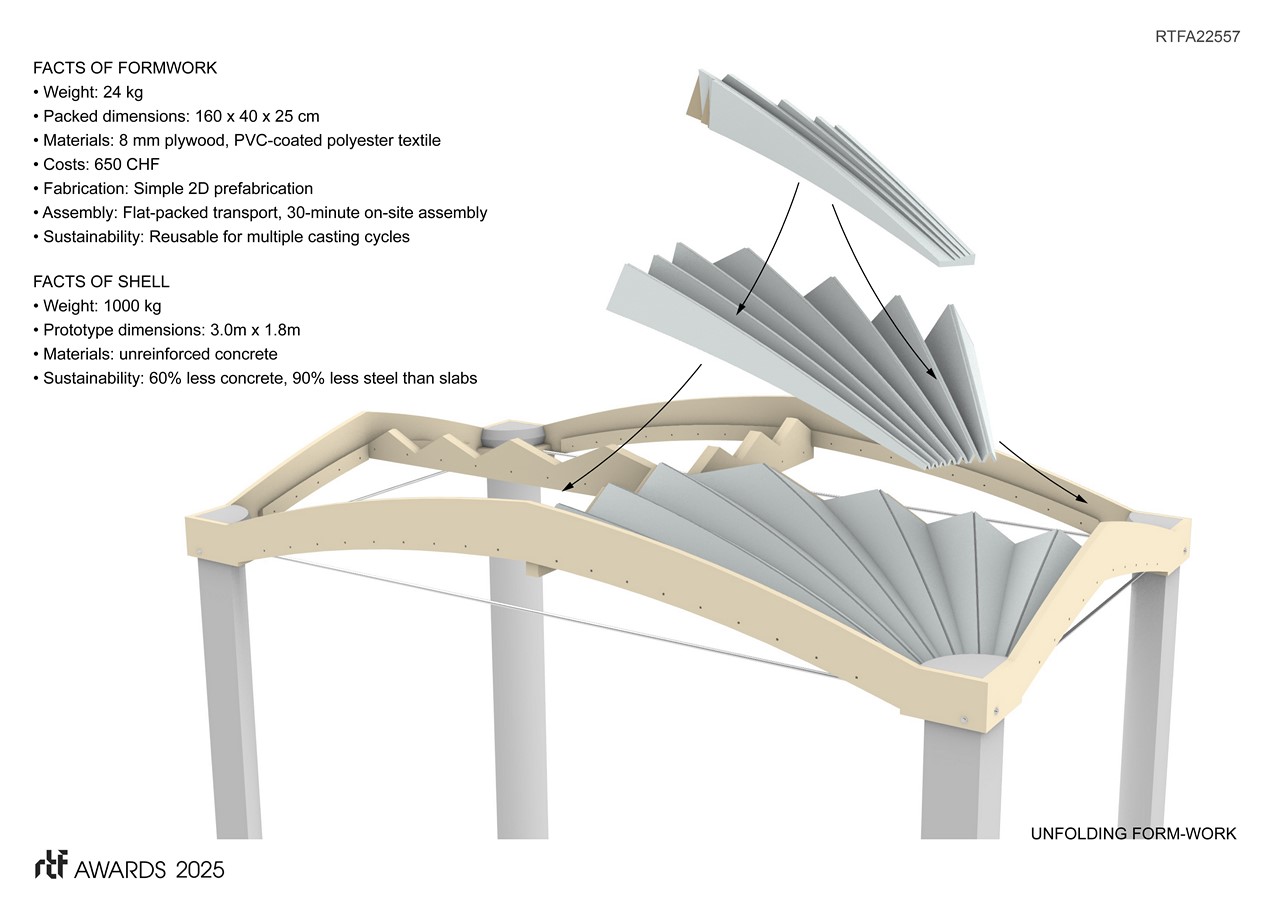

Traditional reinforced concrete slabs are structurally inefficient, requiring large amounts of concrete and steel reinforcement to compensate for tensile forces. Unfold Form takes a different approach, using structural geometry instead of excess material to achieve stability. Inspired by Gothic vaulting, the system replaces inefficient slabs with a thin, ribbed, funicular concrete shell, reducing concrete by 60% and reinforcement steel by 90% compared to conventional slabs.

This significant reduction in material usage lowers embodied carbon by allowing for lighter, more efficient structures. The vault’s expressive ribbed geometry results directly from fabrication and structural logic, where the formwork’s creases control the shell’s shape while providing essential stiffening.

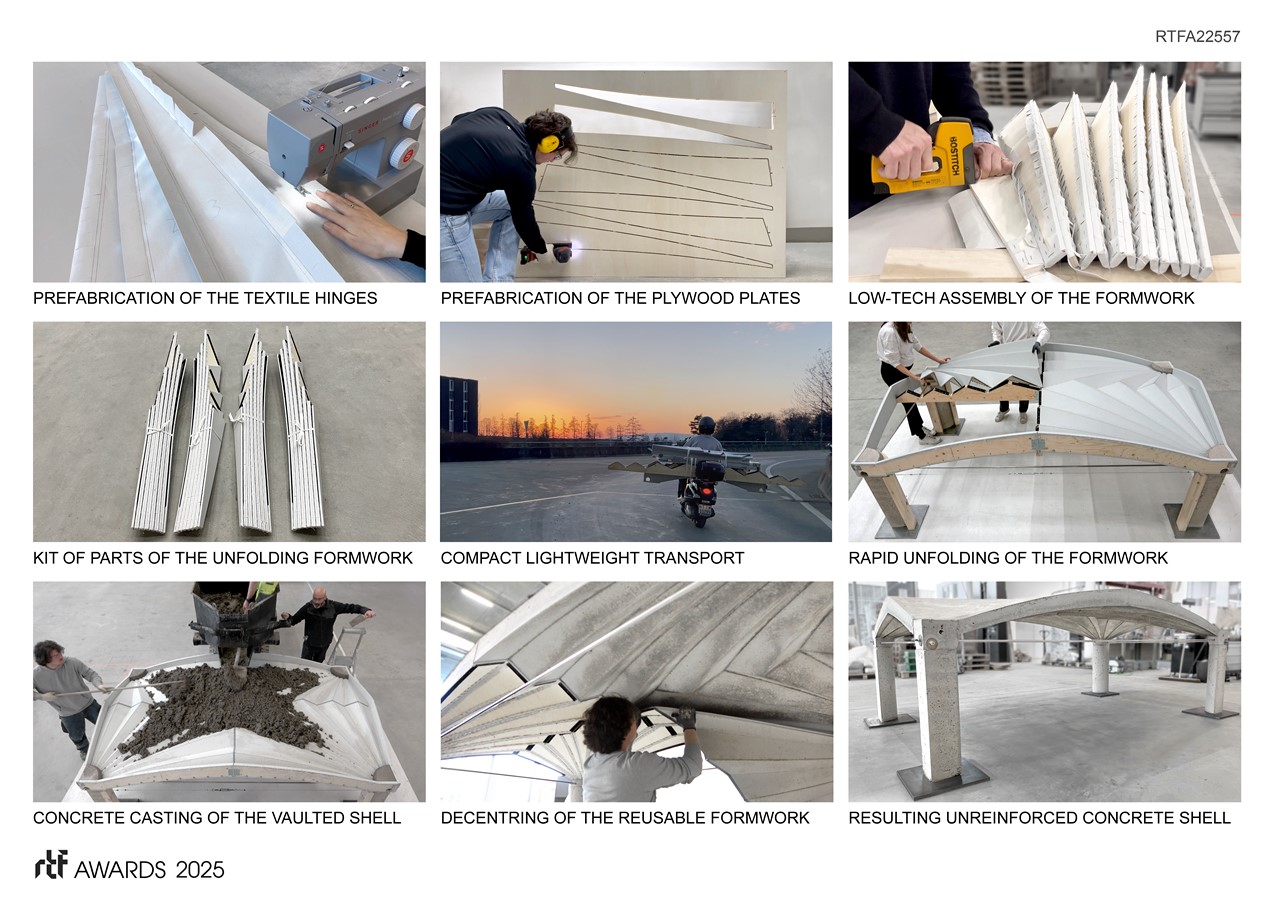

Geometric Principles also for the Formwork

Formwork is a major source of waste and inefficiency in construction. Most custom formworks are bulky, costly, and single-use, often relying on digital fabrication, which limits accessibility in many contexts. Unfold Form instead introduces a self-supporting, reusable formwork system made from bending-active plywood plates and flexible textile hinges, enabling flat-packed transport and quick on-site assembly.

This lightweight, geometrically controlled system is durable and designed for multiple casting cycles, reducing waste and enhancing fabrication efficiency. The resulting corrugations not only improve structural performance but also define a distinct architectural expression, playing with light and shadow to create a refined, intricate ceiling pattern.

Scalability and Global Adaptability

Unfold Form is designed for both high-tech and low-tech applications, making it a globally adaptable solution. It can be fabricated using simple 2D cutting techniques, such as CNC machining or manual jigsaw cutting, allowing for local production and assembly by untrained labour—fostering inclusive and accessible construction.

Beyond vaulted floors, the curved-crease unfolding concept has potential applications in funnel columns, roofs, arcades, and other lightweight structural elements. Ongoing research explores bio-based concrete alternatives, further enhancing sustainability.

Conclusion

Unfold Form demonstrates how material efficiency, structural intelligence, and fabrication logic can shape expressive architecture. By using geometric principles rather than material excess, it presents a scalable, sustainable design strategy that integrates structural performance with distinctive aesthetics, offering a fresh perspective on low-carbon construction.